Air Core chucks are available in sizes 4″, 5″, 6″, as part of the standard manufacturing program. The 3″ is only available as a mechanical chuck since in most cases a 3″ dia airshaft is better and more economical.

Air Core chucks are available in sizes 4″, 5″, 6″, as part of the standard manufacturing program. The 3″ is only available as a mechanical chuck since in most cases a 3″ dia airshaft is better and more economical.

8″ 10″ and 12″ are available only as a lug type. Custom and metric diameters are also manufactured. Many special sizes can be manufactured on a custom basis. Availability of maximum bore sizes for certain chucks should be investigated prior to ordering.

- The LR3 Series chucks are a tire type of chuck recommended for light duty applications. For heavy loads an air shaft is recommended and would be cheaper. Maximum bore size is 1 3/8″ diameter. LR3SS is a shaftless chuck.

- The LR4 Series chucks are a tire type of chuck with bore sizes to fit up to 2 3/8″ diameter shafts. LR4SS is a shaftless chuck

- The LR5 Series chucks are a tire type of chucks with bore sizes to fit up to and including standard 3″ air shafts.

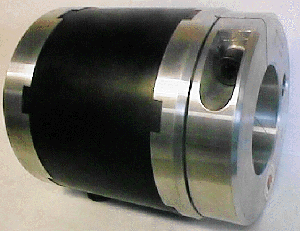

- The LR6 Series (THE SAFE CHUCK)

- The LR6 series chuck, for 6″ cores, is the most popular chuck in our manufacturing program. It was designed with the help of some of our customers, safety being the main factor. The LR6 chuck has an internal bladder protected by aluminum leaves, which protect the air bladder from being cut, and also limit the expansion of the chuck so it wont “blow-out” if inflated outside of a core. The gripping element is a tough rubber compound that will grip all types of cores. It is easily and economically replaced when worn. The LR6 chuck is available with adapters for many bore sizes, and is usually stocked in 2.950″ bore for standard AIR SHAFTS. It is available with a double split collar clamp, a single split clamp, and a set screw lock.”Tie Tube ” option is available when multiple chucks are used in a single core. This allows numberous chucks to be inflated and deflated from the end chucks.

- The #1641 valve is the only valve recommended for any make of core chucks, since it closes quicker and is easier to obtain higher pressures than the push button valves. The small air chamber in chucks makes them extremely susceptible to loss of air pressure, reducing the grip on the core. Low air pressure causes excess wear and premature failure.The ST-125 push button valve is available but is supplied at the customers risk.

CHUCK BORES:

Normally chuck bores are supplied to a tolerance of plus .010″ of the shaft size. This is in order for the chuck to run as true as possible and still be easily slid on or off a shaft. Closer tolerances are available when required.Adaptors are available for square shafts and small diameter shafts.

When ordering chucks for air shafts it is recommended that the shaft be checked for size, since shafts can be supplied with non common diameters

NOTE: Air Chucks are the same as Air Shafts. They must be inflated to the correct air pressure to perform properly, use with low air pressure will cause the roll to slip and wear out the chuck.The recommended air pressure in the chuck is 85-90 psi or approx. 6 Bar. Use with lower pressure will void the waranty.